Christian,

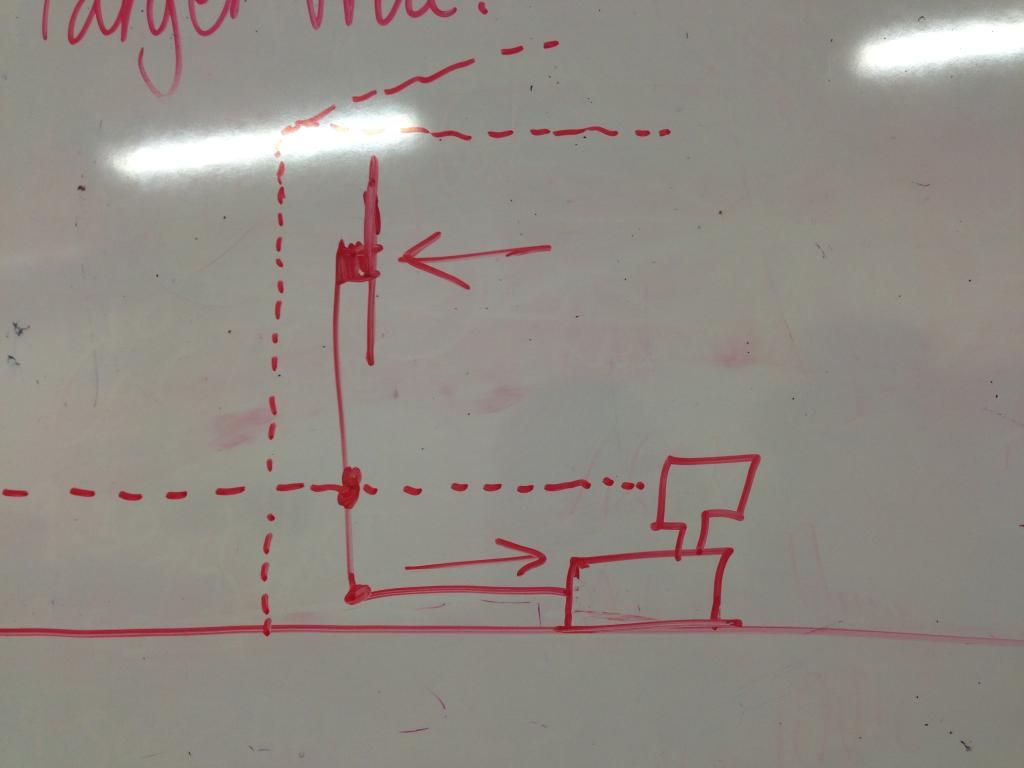

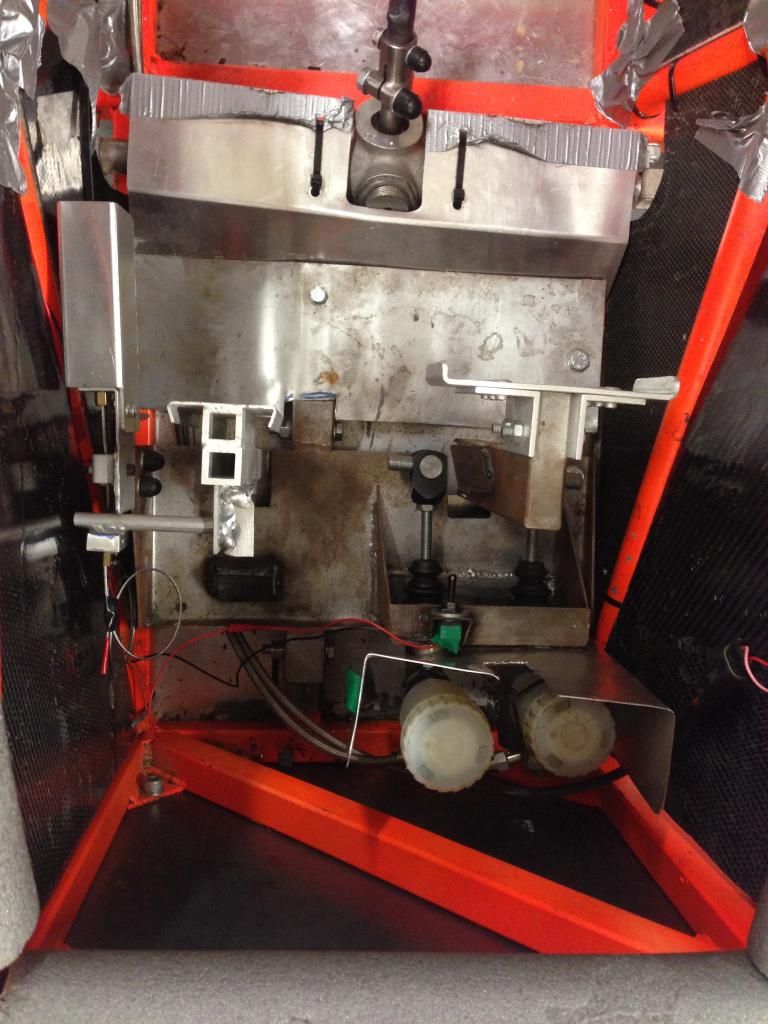

I don't believe there is anything stopping you from running you steering link from upright to upright, though I imagine you will have a hard time packaging it. Also on steering: the ADFA car shown above had issues at comp (may have been 2009) with a very similar design wherein they had to run their wet tyres in order to meet ground clearance rules due to the location of their steering rack. At least that is what I was told, and they were certainly running wets when the weather was fine. Also, there's obviously some linearity concerns with those ADFA steering rods, but you're probably already aware of that. Just some things to be aware of with this type of design.

|

|

Reply With Quote

Reply With Quote