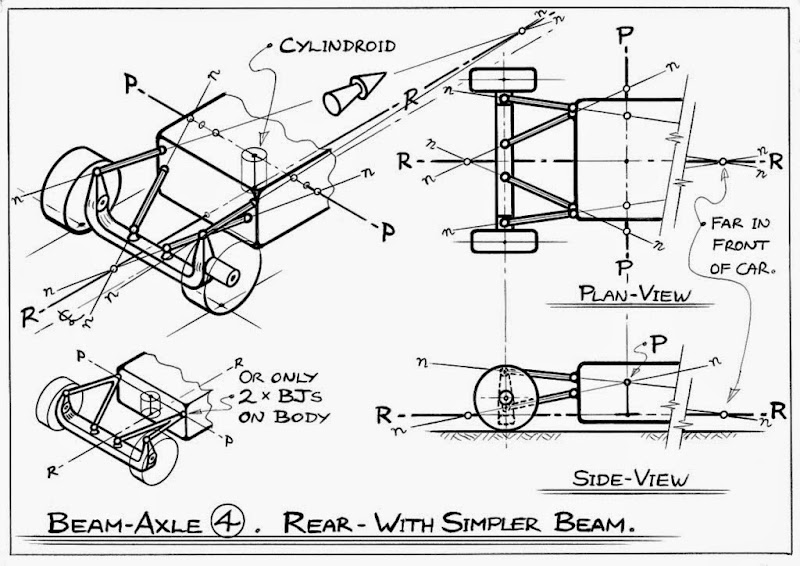

BEAM-AXLE (3) . REAR - VARIATION ON B-A(2).

========================================

This layout is very close to B-A(2) above. This Axle has the same three attachment points as before, but its structural shape is changed from a triangle to a "Y". Either Axle shape would work equally well in either of these two sketches. The choice of Axle shape depends on other packaging requirements.

The two major differences with this layout relate to the way the same four n-lines have been realised with different links.

In B-A(2) the two rearmost n-lines, which intersect R behind the car, have links that go from their Axle connections FORWARD to the Body. Here the links for these two n-lines go from the Axle REARWARD to a single connection on the centreline of the Body, and behind the axle-line.

This, of course, is only desirable if there is some suitable Body structure in this aft position. I would suggest this layout for a car that has a "backbone" chassis, and is perhaps a front-engine-rear-drive, with a diff or transaxle mounted between the rear-wheels. This way the rearmost suspension point on the Body can share the strong chassis structure already needed for the final drive.

(Edit: This De-Dion B-A would well suit a Lotus-7/Clubman type car, especially if built with a backbone chassis (as per the 1960s Lotus Elan).)

The second difference is that the two front n-lines are now realised by a "Ball-in-Tube" joint, rather than the earlier wishbone. See detail at bottom-left of sketch. The 4-DoF, or 2-DoC, "B-T" joint is Kinematically very similar to the wishbone. Both produce a "planar-pencil" of n-lines that amounts to all the straight-lines that pass through a single point, and lie in a flat plane, and look somewhat like the spokes of a wagon-wheel.

In both cases P always lies somewhere in this plane. So P always lies in the plane of the wishbone, or it lies in the plane that passes through the centre of the B-T Ball and is perpendicular to the centre-axis of the Tube. The main Kinematic difference is that the n-lines of the B-T joint maintain the same angle (wrt Body here) throughout its range of movement, whereas a wishbone's n-lines change their angle as the wishbone pivots on the Body.

Practically, the B-T joint is very compact, but not suited to large travel. In the layout shown the B-T joint would only require a short travel, much less than the vertical wheel travel. In the production car world such a joint would be made as a one-piece rubber bush, which combines the rotation of the Ball plus the short axial plunge of the Tube.

Also worth noting here, is that this layout works as if the Body is connected via the R-revolute to a middle-link, and the middle-link is then connected via the P-revolute to the Axle. This is the OPPOSITE way around to all the previous sketches, which are closer to Body-P-R-Axle. The advantage of this layout is that R is thus very stable wrt Body, throughout the suspension's range of motion. This means less chance of adverse Axle-steer effects in the middle of bumpy corners.

Also note that the big separation between the two Body attachment points (ie. at front and rear of R, and along the Body's strong "backbone") implies good potential stiffness of the linkage against Axle-steer effects. But, as always, the "stiffness" of any chain is governed by the stiffness of its weakest link.

Z

|

|

Reply With Quote

Reply With Quote